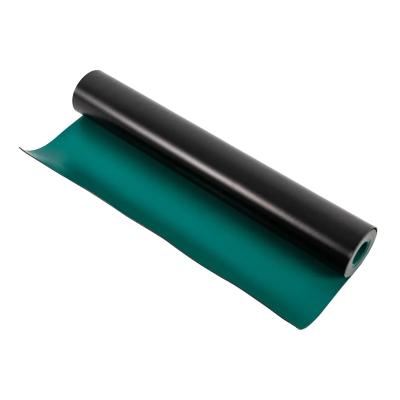

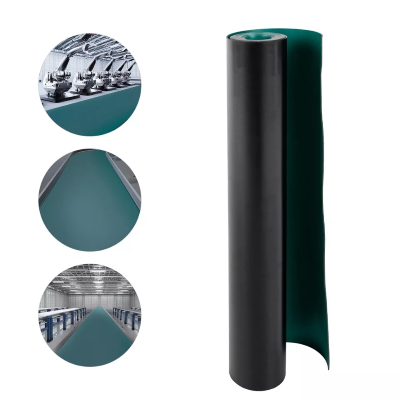

FR0601 ESD Anti Static Rubber Mat

Surface layer: green, black, gray, blue. (Dull and shiny).

Resistance: 10^6-10^9ohm

Bottom layer: black.

Electrostatic dissipation time< 0.01S

Products

Products DETAILS

FR0601 ESD Anti Static Rubber Mat

The Anti-Static (ESD) Rubber Mat is a critical component for creating an electrostatic discharge (ESD)-safe workspace. Designed to protect sensitive electronic components from static electricity, these mats provide a controlled path to ground while ensuring durability and ease of maintenance.

Key Features:

1. Static Dissipative and Conductive Layers:

- Two-layer or three-layer design with a static-dissipative top layer and a conductive bottom layer for effective ESD control.

- Provides a low-resistance pathway to ground, ensuring safe dissipation of static electricity.

2. Durable Rubber Material:

- Made from high-quality rubber, resistant to wear, heat, and chemicals, ensuring long-lasting performance.

- Anti-slip texture enhances safety and stability in the workspace.

3. Compliance with ESD Standards:

- Meets industry standards such as ANSI/ESD S20.20 and EN 61340-5-1, making it suitable for static-sensitive environments.

4. Versatile Sizes and Colors:

- Available in various sizes (e.g., 600 mm x 1200 mm, 1000 mm x 2000 mm) and customizable options for specific workstation requirements.

- Common colors include green, blue, and gray to suit different aesthetic or functional needs.

5. Customizable Grounding Options:

- Features built-in 10 mm snap connectors for attaching grounding cords, ensuring seamless integration with ESD systems.

- Can be paired with wrist straps, ground cords, and other ESD accessories for complete protection.

6. Heat and Chemical Resistance:

- Withstands soldering heat, making it ideal for electronics assembly and repair.

- Resistant to common workplace chemicals, ensuring easy maintenance and durability.

Applications:

- Electronics Manufacturing and Assembly: Protects sensitive components from ESD during production and testing.

- Repair and Maintenance: Ideal for workstations handling circuit boards and electronic devices.

- Laboratories and Testing Facilities: Ensures static-safe environments for handling delicate instruments.

- Cleanrooms: Compatible with ESD-safe and contamination-controlled areas.

- Static-Sensitive Workspaces: Provides reliable ESD protection for any environment handling electronics.

Benefits:

- Reliable ESD Protection: Prevents damage to sensitive electronic components caused by static electricity.

- Durability: High-quality rubber construction ensures long-term performance.

- Versatility: Suitable for various environments and applications.

- Easy Maintenance: Resistant to stains, cuts, and chemicals, making cleaning and care simple.

- Compliance: Meets global ESD standards for static-safe workspaces.

Care and Maintenance:

-

Cleaning:

- Use a mild ESD-safe cleaner to maintain the mat’s surface and conductivity.

- Avoid harsh chemicals or abrasive cleaning tools that may damage the mat.

-

Testing:

- Periodically test the mat’s resistance using an ESD tester to ensure proper functionality.

-

Storage:

- Store the mat in a dry, flat position when not in use to prevent warping or damage.

Specifications:

- Material: Durable rubber with static-dissipative and conductive layers.

- Thickness: Typically ranges from 2 mm to 3 mm.

- Surface Resistance: Static-dissipative top layer (10⁶ – 10⁹ ohms) and conductive bottom layer (10³ – 10⁵ ohms).

- Colors: Green, blue, gray, or custom options.

- Size Options: Standard and customizable dimensions.

-

Snap Connectors: Built-in 10 mm snaps for grounding cords.

Performance index of Dissipative Table/Floor Mat

Dissipative Table Mat/Floor Mat

Specification

Color

Static Dissipation layer

Surface resistance

107-109

1.2mx*10mx*2mm(T)

1.0mx*10mx*2mm(T)Green, blue,

gray, blackFriction static potential V

<100

Conductive layer (black bottom)

Surface resistance

≤106

Friction static potential V

<60

Static voltage attenuation period

5000 – 500V

<1.9s

Flame retardation

GB4609-84, FV-0 (less than 10S)

Volume resistance

107-1010Ωcm

Physical performance index of Dissipative Table/Floor Mat

No.

Description

Test reference

Results

1

Tensile strength

GB 1040

3.6Mpa

2

Fracture elongation

GB 1040

188%

3

Tear elongation

GB/T 529

20.6KN/m

4

Rebound elasticity (the specimen is laminated with 6 layers of sheets)

GB/T 1681

14%

5

Impact embrittlement temperature (no cut)

GB 5470

No damage

at -25℃

6

Permanent compression change rate, 70℃*22h, compression 25%

GB 10654

17.90%

7

Hot air ageing

Tensile strength change rate

GB/T 7141

8.00%

Fracture elongation change rate

-3.80%

Weight loss on heating

1.08%

Remarks

Test according to national standards: GB 1040, GB/T 529, GB/T 1671, GB 5470, GB 10654 and GB/T 7141.

Optional Accessories:

- Grounding Cords: Connect the mat to an ESD ground point for effective discharge.

- Wrist Straps and Heel Straps: For comprehensive ESD protection.

-

Edge Trim: Protects the mat's edges and enhances its appearance.

Installation Guidelines:

-

Workspace Preparation:

- Ensure the work surface is clean, dry, and free from sharp objects that may damage the mat.

- Ensure the floor or surface is compatible with ESD grounding methods (i.e., conductive or static-dissipative flooring).

-

Positioning the Mat:

- Lay the mat flat on the surface where it will be used.

- Ensure the conductive bottom layer is in direct contact with the grounded surface or ESD-safe flooring to complete the grounding circuit.

- Mats should be positioned to cover the entire workspace area where static-sensitive components will be handled.

-

Grounding:

- Attach the mat’s 10 mm snap connector to a grounding cord (such as FR0509 ESD Ground Cord) that is connected to a proper ground (either via the building’s electrical system or a dedicated grounding system).

- Ensure that the grounding cord has a resistor (typically 1 MΩ) to limit any current in case of an electrical surge.

-

Ensuring Proper Coverage:

- For larger workstations, multiple mats can be connected together using ESD connectors to cover a larger area.

- Ensure that the entire workspace is covered to prevent static build-up.

-

Sealing and Edge Protection:

- For added durability and aesthetics, consider applying edge trim around the perimeter of the mat. This helps to prevent fraying and damage to the edges over time.

- Edge sealing can also ensure the mat stays securely in place and minimizes the risk of movement.

Certifications:

Anti-Static (ESD) Rubber Mats typically comply with the following industry certifications:

-

ANSI/ESD S20.20:

- The standard for ESD control in electronic manufacturing environments in the United States, specifying the requirements for an ESD control program.

- Ensures that mats provide adequate grounding and that the static dissipation rates are safe for sensitive electronics.

-

EN 61340-5-1:

- The European standard for ESD control that outlines the necessary measures to protect electrical and electronic devices from static discharge.

- Ensures that ESD mats meet resistance and conductivity levels that prevent the damage to sensitive components.

-

IEC 61340-5-2:

- An international standard that provides guidelines for handling electrostatic discharge (ESD) and emphasizes the importance of protective equipment, such as mats, wrist straps, and grounding systems.

-

RoHS Compliance:

- Mats are generally RoHS (Restriction of Hazardous Substances) compliant, meaning they do not contain harmful substances like lead or mercury, making them safe for use in cleanroom or environmentally-conscious environments.

-

REACH Compliance:

- Ensures that materials used in the mats are safe and meet the EU REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations.

Bulk Purchasing Options:

-

Custom Orders:

- Manufacturers can customize the mat’s size, color, thickness, and snap connector types to suit your specific requirements. Custom lengths, widths, and edge finishes can also be requested.

-

Discounts for Large Orders:

- Bulk pricing is often available for larger orders (e.g., for setting up multiple workstations or for manufacturing facilities). Discounts usually increase with larger quantities.

- Many suppliers offer volume-based pricing where larger purchases come with lower unit costs.

-

Custom Branding:

- For companies looking to create a branded workspace or for promotional purposes, mats can be customized with a company logo or branding.

-

Freight and Delivery:

- Bulk orders may come with negotiated shipping rates, especially for international deliveries.

- Some suppliers offer drop shipping for large-scale installations to save time and streamline logistics.

-

Lead Times:

- Depending on the supplier and order size, lead times for bulk orders can vary. Typically, custom orders may take 2–4 weeks for manufacturing and delivery, while standard orders may take less time.

-

Support and Service:

- Many manufacturers and distributors offer post-purchase support, including installation assistance, troubleshooting, and testing of the mats’ resistance to ensure compliance with ESD standards.

-

Sample Orders:

- Before placing a large order, companies often have the option to purchase sample mats to test their compatibility with existing systems and check their quality.

Would you like assistance with finding suppliers, getting a quote for bulk orders, or assistance with testing procedures? Let me know if you'd like to dive deeper into any of these areas!

-