PL-G5 ESD Polyester FabrIc

Fabric Code: PL-S5

Composition: 98% Polyester 2% Antistatic

Width: 150cm

Weight: 170 (±5%) g/m²

Braid: 3/1 Twill

Conductive: 5mmX5mm Grid Fabric

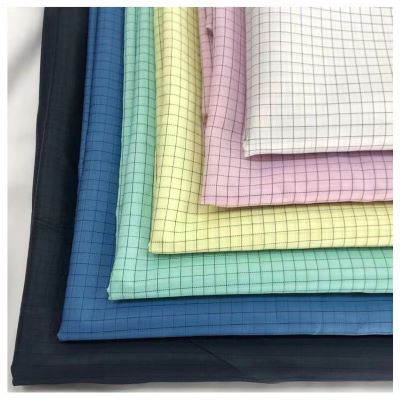

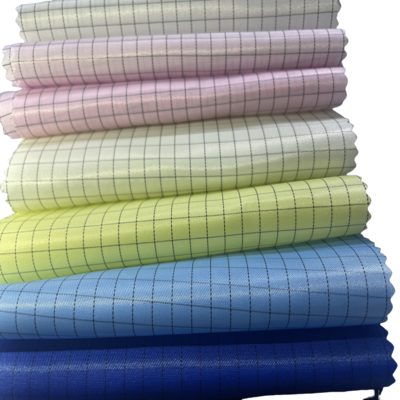

Color: White, pink, Blue, Green, Dark and so on

Standard: EN 1149-1-3-5 , IEC 61340-5-1

Products

Products DETAILS

PL-G5 ESD Polyester FabrIc

1. Technical Description

PL-S5 Antistatic ESD Polyester fabric is a high-performance textile woven with a blend of polyester and conductive fibers, designed specifically to mitigate the effects of electrostatic discharge (ESD). This fabric is engineered to offer permanent antistatic properties, ensuring that it meets the stringent requirements of various industries where static electricity control is crucial.

2. Features:

1)Permanent Antistatic Properties:

---Made from polyester fibers mixed with conductive carbon-added yarns to dissipate static charges efficiently.

---The fabric is treated to maintain antistatic properties over time, even after industrial laundering.

Silicone-Free, Lint-Free, Dust-Free:

---The PL-S5 fabric does not contain any silicone, ensuring that it will not interfere with sensitive processes or equipment in controlled environments.

---Its lint-free and dust-free nature makes it ideal for use in cleanrooms and other environments where cleanliness is essential.

2) Durability:

---The fabric is designed to withstand over 60 industrial washes without compromising its performance, ensuring long-term functionality.

---It is highly resistant to wear and tear in harsh working conditions.

3) Standards Compliance:

---The fabric complies with EN 1149-5 (European standard for electrostatic properties of protective clothing) and IEC 61340-5-1 (international standard for ESD protection), ensuring that it meets global safety and performance standards.

3. Customization Options:

1) Color Variability: The fabric can be produced in any color, with special options like neon colors for high-visibility applications.

2) Lamination Options: Can be laminated with a barrier membrane for additional protection against liquid or particulate contamination.

3) Added Functionalities:

---Water and liquid repellent treatments can be incorporated.

---Antibacterial properties can be added to enhance hygiene and prevent microbial growth.

---Tailored designs for special corporate or industrial needs are possible.

4. Applications:

PL-S5 Antistatic ESD polyester fabric is used to manufacture a wide range of protective garments and equipment, including:

1) Protective Clothing:

---Antistatic ESD Aprons

---Antistatic ESD Shirts, Antistatic Vests, Antistatic Jackets, Antistatic Trousers

---Antistatic Coveralls and Antistatic Overalls

---Antistatic Cleanroom Boots

---Antistatic Berets and Antistatic Hats

2) Cleanroom and ESD-sensitive Environments:

Used in environments such as semiconductor production, electronics manufacturing, and other high-precision industries where static control is paramount.

3) Industries & Sectors of Use:

The fabric is widely utilized in sectors where static electricity poses a risk, including:

---Cleanroom Garments: Ideal for cleanrooms where static control and cleanliness are critical (e.g., semiconductor, pharmaceutical, and electronics manufacturing).

---Electrical & Electronics Industry: Used in ESD-sensitive zones such as electronic card production and assembly lines.

---Cosmetic & Explosive Production: Used in controlled environments where static could lead to dangerous sparks.

---Military, Firefighting, and Hazardous Industries: Utilized in protective wear for military personnel, welders, firefighters, and hazardous material handling.

---Mining, Shipyards, Power Plants: Suitable for workers in heavy industries where static discharge can affect sensitive equipment or processes.

4) Manufacturing & Quality Assurance:

PL-S5 is produced by Shenzhen Fairtech, a company specializing in advanced textile solutions. All fabrics are manufactured in-house under strict quality control processes to ensure high-performance standards. We offer a customer-centric approach, with the ability to develop custom fabrics based on specific requirements.

5) Custom Development:

If the available fabric options do not fully meet your needs, our team of textile engineers is ready to collaborate with you to design and produce tailor-made ESD fabrics, including:

---ESD Antistatic Cotton

--- Cotton/Polyester Blends

---ESD Fleece Materials

Contact Us:

For more information or to discuss your specific fabric requirements, feel free to contact us. We are committed to providing the best technical fabrics and solutions to meet your industry's needs.