FR31 ESD Anti Static Vinyl Tile

Material: PVC

Thickness: 2mm/3mm/2.5mm

Size: sheet/roll size

Product name: Conductive PVC Tile

Application: Industry/ Office/ Hospital/Cleanroom

Color: Customized Color

Feature: Conductive, Electric Disspasive

Raw material: PVC

Package: Roll/ Pieces

Thickness: 2mm/2.5mm/3mm Certificate: ROHS & ESD Compliant

Surface Resistance: conductive tile 10^4~10^6 ohm

Usage: Indoor Floor

Products

Products DETAILS

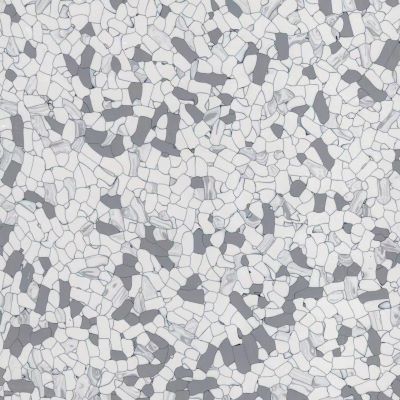

FR31 ESD Anti Static Vinyl Tile

The FR31 ESD Anti-Static Vinyl Tile is a high-performance flooring solution designed to provide electrostatic discharge (ESD) protection while maintaining durability, cleanliness, and aesthetic appeal in environments requiring strict ESD control.

Key Features:

-

ESD Protection:

- Engineered with electrostatic dissipative properties, these tiles effectively dissipate static charges to ground, protecting sensitive equipment and electronics from ESD damage.

- Maintains a surface resistance of 1.0 x 10⁶ to 1.0 x 10⁹ ohms, ensuring compliance with industry ESD standards.

-

Durability:

- Made from high-quality vinyl, the tiles are resistant to wear, abrasion, and impact, ensuring long-term performance in high-traffic areas.

- Resistant to common chemicals, stains, and moisture, making them ideal for harsh industrial environments.

-

Cleanroom Compatibility:

- Designed for low particle shedding and easy cleaning, these tiles are suitable for use in cleanrooms and other contamination-sensitive environments.

- Smooth, non-porous surface ensures hygiene and prevents the accumulation of dirt and contaminants.

-

Slip Resistance:

- Provides a non-slip surface for improved safety, reducing the risk of accidents in the workplace.

-

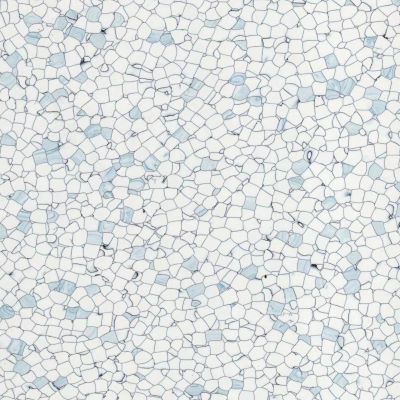

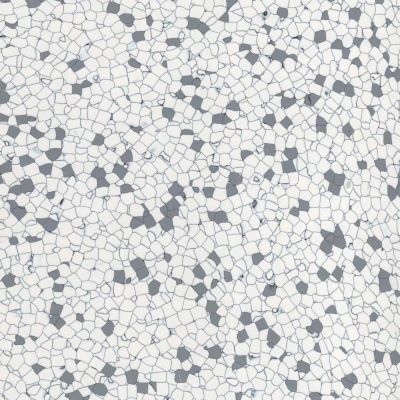

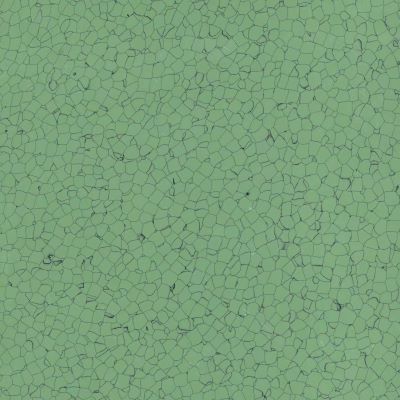

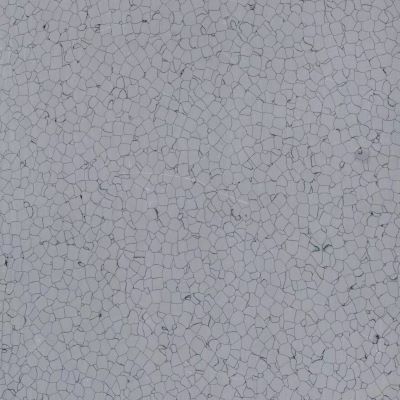

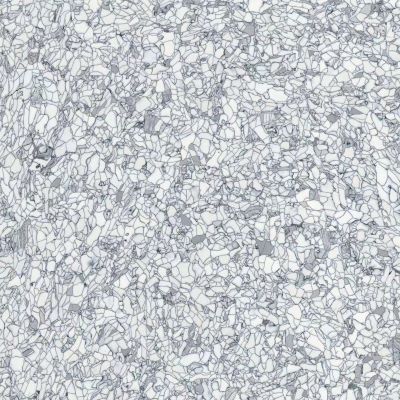

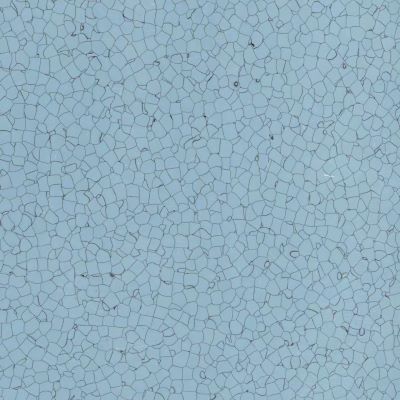

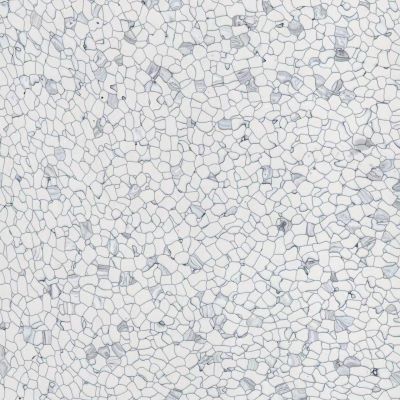

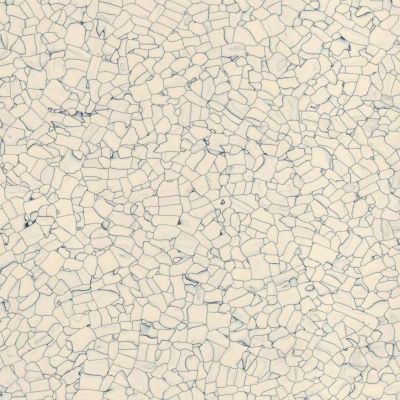

Aesthetic Appeal:

- Available in a range of colors and patterns, the tiles can enhance the visual appeal of workspaces while maintaining their functional properties.

- Uniform appearance helps create a professional and organized environment.

-

Ease of Installation:

- Modular design allows for quick and simple installation with minimal disruption to operations.

- Can be installed using standard adhesives, with proper grounding connections to ensure ESD effectiveness.

-

Low Maintenance:

- Requires minimal upkeep; regular sweeping and mopping are sufficient to keep the tiles clean and functional.

- Retains its ESD properties even after repeated cleaning.

Applications:

The FR31 ESD Anti-Static Vinyl Tile is ideal for use in environments where ESD-sensitive operations are conducted, including:

- Electronics Manufacturing: Protects delicate components during assembly, testing, and repair.

- Cleanrooms: Ensures compliance with ESD and contamination control requirements.

- Data Centers: Safeguards servers and IT equipment from static discharge.

- Pharmaceutical Production: Reduces ESD risks while maintaining hygiene.

- Laboratories: Provides a controlled environment for sensitive experiments and research.

- Aerospace and Defense: Ensures the protection of critical equipment and materials.

- Medical Facilities: Protects sensitive diagnostic and therapeutic devices.

Technical Specifications:

|

|

|

|---|---|

| Material | High-quality vinyl |

| Surface Resistance | 1.0 x 10⁶ to 1.0 x 10⁹ ohms |

| Tile Size | Customizable (standard options available) |

| Thickness | Typically 2mm to 3mm |

| ESD Performance | Electrostatic dissipative |

| Slip Resistance | Compliant with safety standards |

| Chemical Resistance | High |

| Maintenance | Easy to clean; low maintenance required |

Installation Guidelines:

-

Surface Preparation:

- Ensure the subfloor is clean, dry, and level. Remove any dirt, grease, or debris.

- Test for moisture to avoid compromising the adhesive and tile bonding.

-

Adhesive Application:

- Apply an ESD-compatible adhesive evenly across the subfloor. Follow the manufacturer’s instructions for drying times.

-

Tile Placement:

- Lay the tiles in the desired pattern, ensuring alignment and proper spacing for a seamless finish.

-

Grounding:

- Connect the tiles to the grounding network using grounding strips or conductive adhesives to maintain ESD protection.

-

Final Inspection:

- Verify the continuity of the grounding system and ensure all tiles are securely in place.

Maintenance Instructions:

-

Regular Cleaning:

- Sweep or vacuum the surface to remove dirt and debris.

- Mop with a cleanroom-compatible, non-abrasive detergent to maintain hygiene.

-

Periodic Testing:

- Test the tiles periodically to ensure they maintain their ESD properties. Replace any tiles showing significant wear or loss of conductivity.

-

Avoid Harsh Chemicals:

- Use only ESD-safe cleaning agents to avoid compromising the tiles' performance or surface integrity.

Benefits of FR31 ESD Anti-Static Vinyl Tile:

- Enhanced ESD Protection: Protects sensitive electronics from electrostatic damage.

- Durability: Withstands heavy foot traffic and harsh conditions without compromising performance.

- Safety and Comfort: Non-slip surface reduces accidents, and cushioned design minimizes fatigue for workers.

- Professional Appearance: Improves the aesthetics of ESD-sensitive environments.

The FR31 ESD Anti-Static Vinyl Tile is a reliable and efficient flooring solution for industries where static control is critical. Its combination of durability, aesthetics, and ESD performance makes it an excellent choice for a wide range of applications.