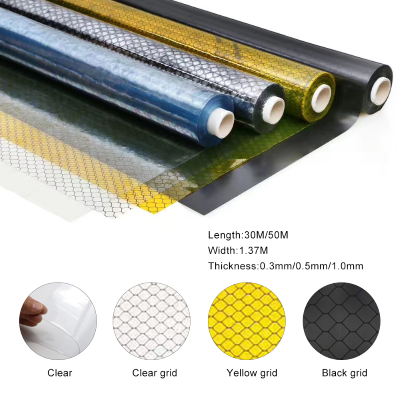

FR0604 ESD Curtain

Material: PVC

Thickness: 0.3mm,0.5mm, 1.0mm

Size: 1.37m X 30m

Processing Service: Cutting

Color: Transparent/Black

Application environment: Cleanroom, Lad, Other Static Protect Area

Surface Resistance: 10^6-10^9 Ohm

Feature: Anti-static,waterproof

Products

Products DETAILS

FR0604 ESD Curtain

The FR0604 ESD Cleanroom Curtain is an essential product designed to provide electrostatic discharge (ESD) protection in cleanroom environments. It helps maintain the integrity of ESD-sensitive areas by controlling static buildup while creating physical barriers to control airflow, contamination, and environmental conditions.

Key Features:

-

ESD Protection:

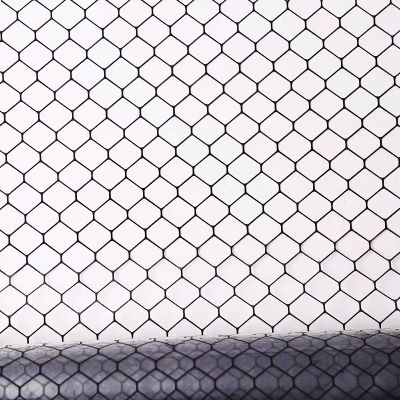

- The FR0604 ESD Cleanroom Curtain is made from special ESD-sensitive materials that dissipate electrostatic charges to ground, protecting sensitive electronics and components from potential damage caused by electrostatic discharge.

- It provides an antistatic surface that prevents the build-up of static electricity in cleanroom areas, reducing the risk of electrostatic discharge (ESD) events.

-

Cleanroom Compatibility:

- Specifically designed for use in cleanrooms, the curtain is particle-free and helps maintain the controlled environment by acting as a barrier to dust, dirt, and other contaminants.

- The materials used are low outgassing, ensuring they do not contribute to particulate or chemical contamination.

-

Customizable and Flexible:

- The curtain can be customized to fit various sizes of cleanroom openings, doors, or partitions. It can be used to section off areas within a cleanroom or provide a quick access entry point without compromising the cleanroom’s integrity.

- The flexible design allows it to be easily adjusted or moved, making it adaptable to changing needs in the workspace.

-

Durability:

- The ESD cleanroom curtain is designed to be durable and withstand the harsh environments typically found in cleanrooms, including frequent cleaning, exposure to chemicals, and constant airflow.

- It is also tear-resistant and offers long-lasting performance.

-

Maintains Airflow:

- The curtain is designed to allow airflow to pass through it while still providing protection from particulate contamination. This helps maintain the cleanroom's air exchange rate (ACH) and minimizes air turbulence.

-

Ease of Installation:

- The FR0604 is easy to install, often coming with mounting hardware or hook-and-loop fasteners, making it a simple addition to existing cleanroom setups.

- The curtains can be easily moved, replaced, or cleaned without major disruptions to the cleanroom's operations.

Applications:

- Cleanrooms used in electronics assembly, semiconductor manufacturing, pharmaceutical production, or any environment where electrostatic discharge can harm sensitive components.

- Laboratories or production areas requiring control over airflow and contamination while maintaining ESD safety.

- Workstations where electronic devices or parts are assembled, tested, or repaired.

Installation Instructions:

-

Determine Placement:

- Decide where the curtain will be installed based on the specific needs of your cleanroom or work area. Typically, ESD cleanroom curtains are used for doorways, partitions, or openings between cleanroom sections.

-

Grounding the Curtain:

- Ensure that the curtain is properly grounded to prevent static buildup. This can be done by connecting the curtain's grounding system to the cleanroom's grounding network. Often, grounding straps or snaps are integrated into the curtain material for easy connection.

-

Mounting:

- Use the provided mounting hardware or hooks to securely install the curtain. It should be mounted so that it can be easily accessed for cleaning or replacement.

-

Check for Proper Function:

- After installation, verify that the curtain effectively blocks contamination while allowing air to flow and ensuring proper static dissipation. Make sure there are no gaps or spaces that could compromise the cleanroom's performance.

Maintenance of FR0604 ESD Cleanroom Curtain:

-

Regular Cleaning:

- Clean the curtain regularly with a gentle cleaning solution to remove any dust, oils, or other contaminants. It’s important to use cleanroom-compatible detergents to avoid introducing particles.

- Avoid using abrasive materials or solvents that could damage the surface.

-

Inspect for Wear and Tear:

- Periodically check the curtain for any signs of abrasion, tears, or damage. If any part of the curtain is compromised, it should be repaired or replaced to maintain the effectiveness of the ESD protection.

-

Check Grounding Connection:

- Verify the grounding connection regularly to ensure that the curtain continues to dissipate static effectively. A continuity test may be used to check the grounding system.

-

Replace as Needed:

- If the curtain becomes too worn, or if cleaning no longer restores its ESD effectiveness, replace it to maintain the cleanroom's protective environment.

Benefits of the FR0604 ESD Cleanroom Curtain:

- Effective ESD protection: Prevents static buildup and potential electrostatic discharge (ESD) events that could damage sensitive components.

- Enhances cleanroom integrity: Maintains the cleanroom's controlled environment by acting as a barrier to dust, particles, and contamination.

- Cost-effective and easy to install: Provides a simple, budget-friendly solution for cleanroom areas requiring ESD control without the need for complex infrastructure changes.

- Versatile and durable: Can be adapted to various cleanroom setups, offering long-lasting protection in a variety of environments.

The FR0604 ESD Cleanroom Curtain is a valuable tool for maintaining both static protection and cleanliness in sensitive areas, ensuring that your cleanroom environment stays compliant with industry standards.