FR0603 ESD Solder Mat

• Brand new and high quality heat insulation pad.

• Resistance to high temperature of 500 °C.

• Several hole location to set screws,IC chips and small parts.

• Make your repair work easy.

• A good partner for hot air gun. Specification:

• Type: Heat insulation pad

• Heat resistance: 500 °C

• Material: Environmentally friendly organosilicone

Products

Products DETAILS

FR0603 ESD Solder Mat

The FR0603 ESD Solder Mat is an essential accessory in environments where electronic components are soldered, offering both ESD protection and soldering surface protection. Below is a detailed breakdown of its features, setup, and maintenance:

Key Features:

-

ESD Protection:

- The FR0603 is designed to dissipate electrostatic charges safely to the ground, protecting sensitive electronic components from ESD damage during the soldering process.

- The mat is made with materials that maintain a dissipative resistance range (typically between 10^6 to 10^9 ohms), which allows static electricity to be dissipated slowly without creating harmful sparks.

-

Soldering Surface:

- The mat provides a heat-resistant surface that can withstand the high temperatures commonly associated with soldering work. It prevents solder from sticking and makes cleanup easier.

- The surface material is non-corrosive and resistant to flux, soldering iron tips, and chemicals typically used in soldering operations, increasing its longevity.

-

Ergonomic and Non-Slip:

- Designed with an anti-slip texture, the mat helps prevent components and tools from slipping off the workbench during assembly or repair.

- The ergonomic features help reduce strain for workers standing during extended soldering tasks, offering some comfort through its cushioned surface.

-

Durable and Easy to Clean:

- The mat is durable and resistant to wear and tear, ideal for environments with frequent soldering tasks.

- It is also easy to clean, allowing for quick removal of solder splashes and flux residues, keeping the work area clean and safe.

-

Anti-Fatigue Properties:

- Like other ESD mats, the FR0603 may also feature anti-fatigue properties, reducing the strain from prolonged standing while working on soldering tasks, promoting comfort and productivity.

Applications:

- Soldering stations in electronics assembly and repair

- Cleanrooms where electronics are assembled or repaired

- Circuit board repair and microelectronics work

- Surface mount technology (SMT) workstations

- ESD-sensitive environments, where even minor static discharges could cause component damage

Setup Instructions:

-

Placing the Mat:

- Lay the ESD solder mat flat on the workbench or soldering station to cover the area where components will be worked on.

- Ensure the entire work surface is covered to prevent exposure to ESD-sensitive components during soldering.

-

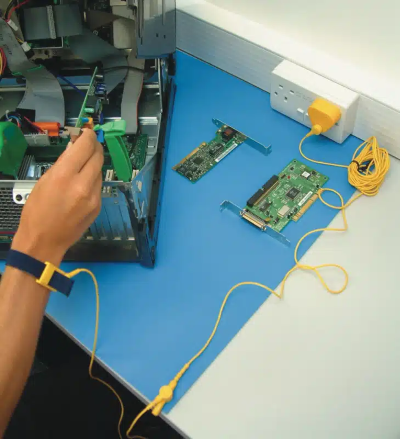

Grounding the Mat:

- Attach the ground snap located on the mat to an ESD ground cord.

- Connect the other end of the ground cord to a common point ground (CPG) to ensure proper grounding of the mat.

- This grounding will safely drain static charges away from both the mat and the components.

-

Using the Mat for Soldering:

- Begin the soldering process on the mat, ensuring that the soldering iron and other equipment are used in accordance with the mat's capabilities.

- If the mat has a non-slip surface, you will find that tools and components stay in place, reducing the risk of accidents during soldering.

-

Wearing Proper Grounding Gear:

- Workers should wear ESD wristbands, connected to the grounding system, to prevent static charge build-up on their bodies from discharging to components during handling.

- Ensure the worker's ESD shoes or heel straps are properly grounded as well.

Maintenance of FR0603 ESD Solder Mat:

-

Regular Cleaning:

- Clean the mat regularly to remove any flux, solder, or debris from the soldering process.

- Use a mild soap solution with a soft cloth to wipe down the mat. Avoid harsh chemicals or abrasive materials that could damage the surface.

- For flux removal, consider using flux cleaners designed for soldering applications, ensuring the mat remains clean and functional.

-

Inspect for Damage:

- Periodically check the mat for any signs of physical damage, such as cracks, burns, or permanent indentations from soldering iron tips.

- Make sure the grounding snap is securely attached and that the mat remains properly grounded during use.

-

Heat Resistance:

- Although the mat is designed to withstand high temperatures, always ensure that the soldering iron tip is not left in contact with the mat for prolonged periods, as this can cause surface damage.

- If the mat shows signs of deterioration due to heat exposure, it may need to be replaced.

-

Testing the Grounding Resistance:

- Regularly test the resistance to ground of the mat using an ESD resistance tester to ensure it falls within the correct range (typically between 10^6 to 10^9 ohms).

- If resistance values are outside the ideal range, re-ground the mat or replace it to maintain effective ESD protection.

-

Storage:

- When not in use, store the mat in a cool, dry place away from direct sunlight, chemicals, or heat sources.

- Avoid folding or rolling the mat tightly to prevent permanent creasing or damage to the surface.

Benefits of the FR0603 ESD Solder Mat:

- Prevents damage to sensitive components by ensuring a static-free environment during soldering.

- Protects the work surface from heat, flux, and solder, extending the lifespan of workbenches and other equipment.

- Improves worker safety by providing a cushioned, anti-slip surface that reduces the physical strain of long soldering sessions.

- Enhances productivity by maintaining a clean, efficient workspace.