FR0601 ESD Anti Static Floor Mat

Antistatic mats help to protect static sensitive components from electrostatic discharge

Products

Products DETAILS

FR0601 ESD Anti Static Floor Mat

Key Features of ESD Mats:

-

Purpose and Function:

- ESD mats help protect static-sensitive components from electrostatic discharge (ESD) by dissipating static charge into the ground.

- They are used on flat surfaces such as workbenches, tables, and floors where electronic assembly occurs.

- The grounding of ESD mats is critical for their effectiveness in neutralizing static electricity.

-

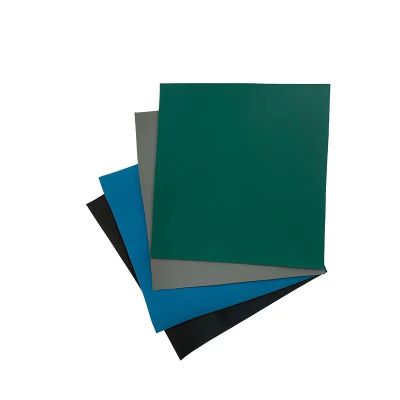

Mat Types:

-

Work Surface/Bench Mats:

- Used on workbenches or tables where assembly takes place.

- Typically have smooth or slightly textured surfaces to reduce glare.

- Available in single-layer, two-layer, and three-layer constructions.

-

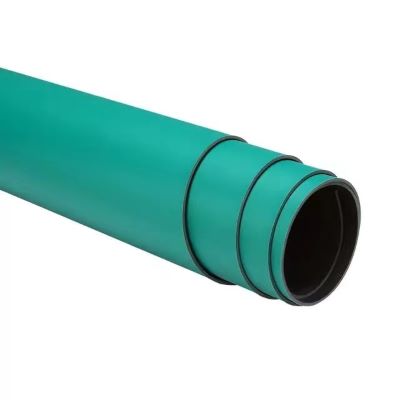

Floor Mats:

- Used to cover the floor of an ESD-sensitive area, preventing static build-up and providing ergonomic benefits to workers standing for long periods.

- Often come with anti-fatigue properties and textured surfaces for better traction.

-

Work Surface/Bench Mats:

-

Electrical Properties:

- ESD mats can be conductive (resistance < 1 x 10^4 ohms) or dissipative (resistance between 1 x 10^4 and 1 x 10^9 ohms).

- Dissipative mats are preferred for handling sensitive electronic components as they slowly dissipate static charges to prevent rapid discharge, which can damage devices.

-

Resistance is typically measured in three ways:

- Resistance to Ground (RTG): Measures resistance between the mat and the ground.

- Resistance to Groundable Point (RTGP): Measures resistance from a specific point on the mat to the ground.

- Resistance Point to Point (RTP): Measures resistance between two points on the mat’s surface.

-

Construction and Materials:

- Vinyl Mats: Cost-effective, flexible, and commonly used for tabletop applications. Ideal for general static dissipation.

- Rubber Mats: Offer better resistance to heat and chemicals, making them suitable for environments involving hot soldering or harsh chemicals.

- Multi-layer Mats: Provide enhanced static dissipation, with a conductive layer (typically carbon) between the top and bottom layers.

-

Applications:

- Cleanrooms (e.g., for microchip production)

- Manufacturing plants for electronics and sensitive equipment

- Repair shops for electronic devices

- Computer server rooms, medical offices, and other environments requiring static control

-

Safety and Comfort:

- Some ESD mats include anti-fatigue features, such as extra cushioning, to improve worker comfort during long periods of standing.

- Slip-resistant surfaces in floor mats prevent accidents.

How to Set Up an ESD Mat:

- Place the Mat: Lay the ESD table mat on the workbench or floor.

- Grounding: Attach a ground snap to the mat and connect it to the common point ground using a ground cord.

- Wristbands: Use an ESD wristband connected to the ground cord to protect workers from static discharge.

- Floor Mat Setup: If using a floor mat, connect it to the ground snap and wear ESD heel straps to maintain grounding while standing.

Testing and Certification:

- It is crucial to purchase certified mats, such as those meeting IEC standards, to ensure that the mats meet the required resistance levels and provide adequate protection.

- Regular testing of ESD mats is necessary to ensure they continue to perform effectively.